Beyond Conventional Display Applications: Cholesteric Reflective LCDs

New cholesteric LC materials and roll-to-roll manufacturing processes have enabled new technologies that have, in turn, inspired new applications and products.

by Asad Khan

THE DISPLAY INDUSTRY has grown and evolved with the times. The last two decades have seen amazing new applications, from laptop computers to large televisions that are mere millimeters thin. At the same time, it is the industry that has had a romance with flexible displays for a long time. Only about a dozen years ago, flexible displays and applications started taking on significant momentum. The energy and hype in the industry has been persistent. Recently, some applications and embodiments have surfaced in limited numbers in the marketplace. These have included displays in flexible smart cards, wrist watches, etc. One must note that there is certainly an abundance of prototypes and technology demonstrators as well as limited low-volume releases in the market using flexible displays from organic LEDs (OLEDs) to electrophoretic displays and even conventional LCDs.

One medium for flexible displays that has found success is the bistable cholesteric technology recently branded as Reflex™ from Kent Displays. This technology has been in the market since 1996 in non-flexible applications such as industrial, digital signage, and instrumentation (see Fig. 1).

Fig. 1: Many products and prototypes have been created using Kent Displays' bistable cholesteric technology, including (clockwise from center top): digital signage, smart cards, store labeling systems, flexible color-changing skins for phones, outdoor signage, and, at center, the Boogie Board tablet.

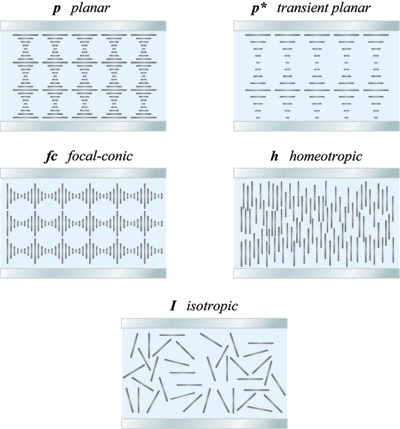

Cholesteric displays are Bragg-reflecting devices in which the liquid-crystal material itself reflects light in the planar texture. The cholesteric liquid-crystal material is arranged in a helical fashion creating so-called textures. The two textures used in bistable cholesteric displays are the planar (p) and the focal-conic (fc) textures (see Fig. 2).

Fig. 2: Key textures include the reflective planar (p) and the transparent focal-conic (fc) states. These two textures are stable in the absence of an external stimulus (such as an electric field or pressure).

The planar texture is reflective and the focal-conic texture is largely transparent, showing the dark absorbing background. Other textures that are involved in electro-optical effects are the transient planar (p*) texture and the homeotropic (h) texture. Transitions take place between these textures through external forces, such as electric fields or applied pressure, to enable operation of cholesteric displays. Phase transitions such as crystal to cholesteric or cholesteric to isotropic take place when the temperature for the system is changed.

There are a variety of passive-matrix drive schemes that can be utilized to switch the displays, and these can be run as fast as about 0.5 msec/row at room temperature. These displays can also be driven by a typical active-matrix backplane. In general, the display architecture is simple; only transparent substrates and conductors are used, with no polarizers, retardation films, backlights, etc.

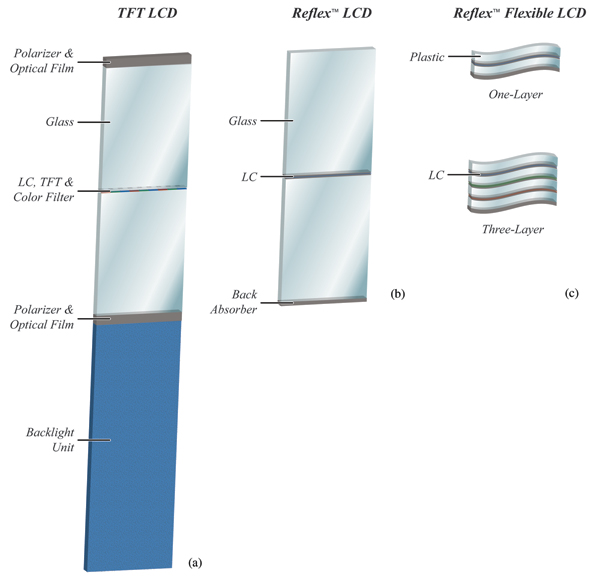

Figure 3 shows a cross-sectional schematic illustration of a conventional TFT-LCD, a bistable rigid glass-based cholesteric LCD, and a flexible cholesteric LCD – the latter in both single-layer and stacked-type three-layer configurations. The thickness of all display types is drawn to scale to illustrate the dramatic differences among them. The benefits of flexibility, thinness, and ruggedness are obvious.

Fig. 3: This cross-sectional schematic illustration shows (a) a conventional TFT-LCD, (b) bistable rigid glass-based cholesteric LCD, and (c) a flexible cholesteric LCD, the latter in both single-layer and stacked-type three-layer configurations. The thickness of all display types are drawn approximately to scale.

Manufacturing Advances

One of the key enabling features of encapsulated cholesteric displays is the development and execution of the necessary manufacturing processing, methods, and tools. Today, writing tablets, electronic skins, and displays for smart cards (all discussed below) are routinely manufactured at the Kent Displays' plant in Kent, Ohio, utilizing continuous roll-to-roll manufacturing. The operation runs 24 hours a day, 7 days a week, and is highly automated. Products from the manufacturing line, such as the Boogie Board, have been shipping since mid-2009. The capacity for the first-generation line has been sufficient for initial product introductions and validation. However, it is already running at maximum capacity. The next-generation line is in design and development at present.

The existence of the first fully automated roll-to-roll production line dedicated to flexible cholesteric-LC-based displays marks a key milestone toward the realization of flexible LCDs in mass production for a variety of applications. The equipment and processes that have been developed by Kent Displays have been instrumental in enabling a viable cost structure for flexible displays as well as creating the capacity and capability necessary for mass production and market entry.

Cholesteric-LC Materials and Applications

Cholesteric liquid-crystalline materials have been used in many different optical and electro-optical devices such as temperature sensors, thermometers, and high-efficiency polarizing films. Cholesteric materials have also been the subject of much research with regard to electro-optical displays. In the last decade, they have been successfully developed into bistable, purely reflective, low-power LCDs. Their high reflectivity, wide viewing angle, and low power due to bi-stability make them an excellent display technology choice for signage applications, hand-held devices, and portable electronic readers.

Color in cholesteric displays comes from additive color mixing. Red, green, and blue primaries can be arranged vertically (stacking1) or horizontally (spatial2). Both have unique benefits and are suited for particular applications. Stacking allows for excellent reflectivity and brightness, whereas spatial color allows for high-contrast and low-cost architecture. Both approaches have been used. Stacking is the predominant approach employed in a variety of applications, from large-area digital signage such as that produced by Magink and AEG-MIS, to high-information-content full-color electronic readers such as those made by Fujitsu. Unconventional applications such as electronic "skins" also employ the stacking structure.

More recently, cholesteric materials have been successfully encapsulated using a phase-separation approach,3 allowing for low-cost roll-to-roll manufacturing while maintaining the inherent properties of conventional cholesteric displays. The encapsulation dramatically ruggedizes the displays and allows for a high degree of flexibility. This then lends itself to the exploitation of applications that were not possible previously.

Because conventional display applications did not seem to fully exploit the features of these cholesteric-LC displays, new and unique applications have been explored, and the subsequent innovations led to three different product lines that share the same underlying technology: writing tablets, electronic skins, and flexible information displays.

Writing Tablets

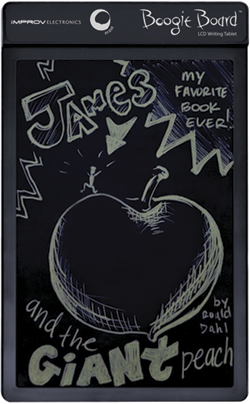

LCD writing tablets based on Reflex technology are in many ways a replacement for chalkboards, whiteboards, and scratch paper. Since these LCD writing tablets use a pressure-sensitive display, the user does not need a special pen to create an image. Even a fingernail or other object can be used to create the desired effect.

The writing tablet display is a simple construction of flexible plastic substrates coated with conducting polymer electrodes.4 It is made from a single pixel, so the construction and the driving electronics are therefore streamlined. Since the construction is from flexible substrates, the product is inherently more rugged than glass-based displays, although it is not meant to be flexed while in normal operation. The initial state of the display is in the focal-conic (fc) texture. External pressure causes the liquid crystal to flow, and the flow re-orients the liquid crystal in the planar texture. The area where pressure is applied therefore appears brighter than the surrounding area. Pressing the erase button triggers the electronics to apply appropriate waveforms to switch the entire "pixel" back to the focal-conic texture, where it appears dark based on the color of the back absorber.

Kent Displays entered the writing-tablet mass market in January 2010 with the introduction of its Boogie Board LCD Writing Tablet from Improv Electronics, a newly formed business unit of Kent Displays (Fig. 4). Global demand for the Boogie Board tablet was immediate and has been sustained.

Fig. 4: This writing tablet – the Boogie Board – is the first mass-produced Reflex LCD made from all flexible materials. It has been in the marketplace since the beginning of 2010 and retails for less than $40.

Similar to all LCDs that are reflective and bistable, the Boogie Board tablet requires no power to generate or retain an image, and only a small amount to erase (supplied by a coin cell battery, which will execute over 50,000 erase cycles). The lower power nature of the Boogie Board further makes it an environmentally friendly product.

The Boogie Board can be used in the home, at the office, in the classroom, on the field, and in the car for a wide range of activities including writing memos and to-do lists, leaving reminders, practicing handwriting/arithmetic, drawing pictures, performing calculations, brainstorming ideas, charting/graphing, playing games, diagramming athletic plays, and more. The product is proving popular in schools, and also with individuals who have speech or hearing disabilities. Kent Displays is actively developing a wide range of new Boogie Board tablets and accessories for 2011. Next-generation Boogie Board tablets will feature different sizes and form factors, image-capture technology, and other new functions/capabilities.

Electronic Skins

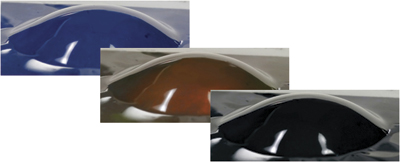

Kent Displays' electronic skins utilize display technology on ultra-thin flexible substrates. When integrated onto all or part of another object's surface, typically a personal electronic device, the skin provides on-demand personalization, usually in the form of a color change that can be initiated as often as desired by engaging a switch or button.

Development of these electronic skins has been an on-going area of focus at Kent Displays for several years.5 The skin uses plastic substrates that are similar to those in the writing tablet. They are coated on one or both sides with conducting polymer. The display is either single layer (for one color) or multiple layers (for multiple colors). Figure 5 shows photographs of a prototype mobile phone with a color-changing electronic skin integrated into the housing. Different colors are realized on the skin by electronically switching.

Fig. 5: A prototype mobile phone features a color-changing electronic skin integrated into the housing. Multiple colors can be realized on the skin by electronically switching. The bare electronic skin is also shown to illustrate its flexibility.

These skins are also manufactured in a roll-to-roll continuous process. Similar to the Boogie Board, the architecture is simple in that there is only one pixel and simple drive electronics. For multiple layers, the display is made in a stacked structure directly on the fully automated production line.

The first-generation Reflex skins display 2–8 different colors depending on the number of substrate/liquid-crystal layers. The skins can be cut into almost any desired shape and can be thermoformed to a device surface. Figure 6 shows thermoformed three-layer full-color electronic skins conformed to a spherical (complex) surface.

Fig. 6: These three-layer full-color electronic skins have been conformed to a spherical (complex) surface by thermoforming. The skins are fully functional and switchable.

While the integration of skin to device represents many challenges, several methods can potentially be utilized, including lamination, in-mold decoration, injection molding, etc. Most of these methodologies have already been demonstrated in the laboratory.

In 2011, Kent Displays will introduce an aftermarket consumer product featuring a Reflex electronic skin. This product will be sold under the Improv Electronics name and is expected to generate consumer demand comparable to that for the Boogie Board LCD Writing Tablet. In part, due to this, the company's developers believe the push into unconventional applications for flexible displays will see significant growth in 2011.

Flexible Information Displays

The application discussed in this article that is closest to one for conventional displays is the product area dedicated to graphical and segmented displays for smart cards. These displays are made with ITO-coated plastic and are either directly (segmented) or passive-matrix (graphical) addressed. The drive schemes allow for low cost and easier integration into thin cards. The encapsulated Reflex-based materials are rugged enough to withstand ISO testing of fully integrated display/cards. Figure 7 shows conceptual ideas for smart-card displays integrated in consumer credit and loyalty/membership cards. Other applications include one-time password (OTP), loyalty, and gift cards.

Fig. 7: Conceptual ideas for smart-card displays integrated in consumer credit and loyalty/membership cards include both segmented and graphical displays.

The graphical and segmented displays for card applications are also manufactured using the same continuous fully automated roll-to-roll production. The input is fully patterned ITO-coated thin plastic substrates. After display production, the displays go through testing and finally bonding to electronics prior to integration into card "inlays." The inlays are then integrated into cards using typical card-making processes such as reaction injection molding, lamination, etc. It is expected that mass-market realization of high-information-content displays in cards will take place in 2012 and beyond.

Competitive Landscape

Approaching unconventional applications in displays requires an understanding of a new competitive landscape and field. Traditional competitors have included other bistable displays, conventional TFT-LCDs, etc. Now, the competitive technologies are white boards, pen and paper, magnetic writing toys, etc. for writing tablets. For electronic skins, the competitors are plastic housings, cases for mobile devices, replaceable fixed color skins, etc. Although there have been publications from other organizations6 that discuss electronic skins since the first publications from Kent Displays, there have been no commercial manifestations of color-changing skins in the market thus far. For smart-card displays, certainly other display technologies are well suited (such as electrophoretic technology from E Ink and SiPix Imaging). However, key competition comes from other security applications such as those based on mobile-phone authentication. Much of this competition and positioning will really be decided by the marketplace. For writing tablets, the initial success and market acceptance of the Boogie Board is an example of validation, adoption, and demand from consumers. It was difficult to predict before the product's success, but easier to explain and justify once the Boogie Board was accepted in the marketplace. 2011 and beyond will demonstrate flexible displays emerging in new and with unconventional applications.

The Path Ahead

The path forward is hard to predict because new, unconventional display applications attract new markets that are largely unknown. A lesson learned from the Boogie Board is that one must find and exploit applications that are best suited for the technology. Flexible displays, in general, will require many new and innovative ideas. Often original equipment manufacturers are not set up to quickly make use of new transformational concepts in display technologies. There are numerous examples of organizations going beyond display manufacturing to incorporate flexible materials in products. These have included Plastic Logic with e-Readers; Polymer Vision with mobile devices with fold-out displays; E Ink with flexible demonstrators, watches, etc.; and Kent Displays with the Boogie Board, electronic skins, etc. These organizations have had to innovate and make products that are designed specifically to make use of the key features of their respective display technologies and its attributes. Following an increase in such product introductions, we will invariably see OEMs making and developing products that use such components. It is then that the flexible display segment will explode on the consumer products arena. It is anyone's guess as to when this will take place – next year, or years from now. What is certain is that it will happen.

References

1M. Okada, T. Hatano, and K. Hashimoto, SID Symposium Digest 28, 1019 (1997); D. Davis, K. Hoke, A. Khan, C. Jones, X.-Y. Huang, and J. Doane, Proc. IDRC 17, 242 (1997).

2F. Vincentini, J. Cho, and L. C. Chien, Liq. Cryst. 24, 4483 (1998); D.-K. Yang, Z. Lu, L. C. Chien, and J. W. Doane, SID Symposium Digest 34, 959 (2003).

3T. Schneider, F. Nicholson, A. Khan, and J. W. Doane, SID Symposium Digest 36, 1568 (2005).

4J. L. West, M. Rouberol, J. Francle, Y. Ji, J. W. Doane, and M. Pfeiffer, Proc. IDRC 15, 5 (1995); T Schneider, G. Magyar, S. Barua, T. Ernst, N. Miller, S. Franklin, E. Montbach, D. Davis, A. Khan, and J. W. Doane, SID Symposium Digest 39, 1840 (2008).

5J. W. Doane, D. Davis, A. Khan, E. Montbach, T. Schneider, and I. Shiyanovskaya, Proc. IDRC 26, 9 (2006).

6T. Koch, D. Hill, M. Delos-Reyes, J. Mabeck, J.-S. Yeo, J. Stellbrink, D. Henze, and Z.-L. Zhou, SID Symposium Digest 40, 738 (2009). •

Asad Khan is Chief Technical Officer at Kent Displays. He has been with the company for over 15 years and oversees a variety of functional areas including product and technology development. He can be reached at akhan@kentdisplays.com.