The Virtues of Quantum Dots

The Virtues of Quantum Dots

When used in conjunction with LED backlighting, quantum dot technology can make LCD performance meet or exceed that of OLED displays.

by Seth Coe-Sullivan

TODAY’s consumers have access to a wide variety of image and video content, and their expectations for performance, most especially picture quality, are high across all delivery platforms. As a result, display suppliers are motivated to push the limits of exceptional picture quality on any and all consumer devices, from small-screen mobile phones to the largest-screen TVs. Meeting the different needs and challenges of this wide range of display devices, where one size certainly does not fit all, requires constant assessment of new technologies.

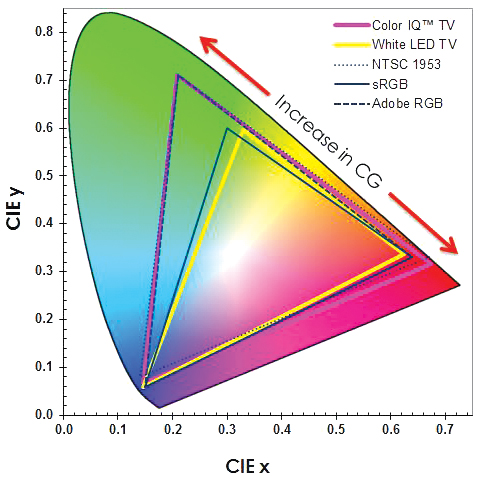

From an industry trends perspective, resolution improvements seem to be offering diminishing returns as we approach the limits of the human eye. Color gamut seems to be ripe new territory, offering consumers a visually appealing quality difference over what they are used to. While the Adobe RGB standard is gaining traction in the prosumer monitor space, the DCI color-gamut standard is increasingly the target for home-theater TVs. Furthermore, future standards such as UHD-1 will include gamut specs that are considerably wider than HD’s Rec. 709, based on the BT.2020 definition.

Displays that can render 100% of the colors within any of these wider-gamut standards are therefore full-gamut displays. Several technologies exist today that enable full-gamut displays, including lasers, OLEDs, and quantum dots (QDs). While laser-based displays have been much discussed, they remain a curiosity due

to the lack of an efficient green light source. For this reason, we will focus this article primarily on the comparison between the most viable technologies for full-gamut displays: OLEDs and quantum dots.

TV makers have long touted OLED displays as the ultimate in picture quality because they can produce saturated colors with extremely high contrast ratios and virtually no motion blur. OLED displays are certainly impressive to look at! LCDs using QD-enhanced backlights are a relative newcomer to displays, but are challenging OLED in market segments such as TV as a high-quality alternative. LCDs with QD backlights meet or exceed OLEDs in a number of display metrics, while offering an easier upgrade model for display makers and consumer-electronics companies alike.

QD and OLED Basics

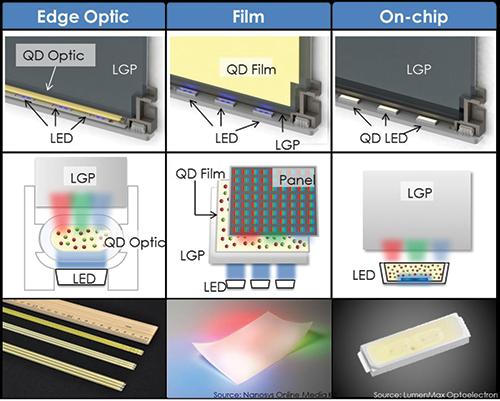

Quantum dot semiconductor nanocrystals are tiny chunks of crystalline inorganic luminescent material that emit saturated light in colors depending on both the material composition and size of the dots themselves. QDs are a part of the light engine [the backlight unit (BLU)] in today’s liquid-crystal displays (LCDs), generating the red and green primaries by downconverting a part of the blue light emitted by a blue inorganic light-emitting device (LED) (Fig. 1).

In contrast, OLED displays directly emit light from each pixel, and hence have no corresponding BLU component. An OLED is an organic light-emitting device in which the emissive electroluminescent layer is a film of amorphous organic (or organometallic) material that emits light in response to an electric current. The OLED structure is a rather complex multilayer film stack in which the molecular design of each layer is dependent on the adjacent layers, nanometer thickness control is essential, and the organic molecules themselves are quite expensive due to the multistep syntheses required. Due to the interdependency of this technology and the intellectual property barriers that are in place, manufacturers have been only slowly making progress on the requisite and numerous manufacturing challenges. On the other hand, LCD construction is more modular with less interdependency between the various functions, and so the modularity of LCDs has allowed the massive industry’s infrastructure to separately optimize and reduce the cost of each component, resulting in tremendous year-over-year cost reductions that have been achieved for well over a decade.

Fig. 1: 3-D, 2-D, and photographic images of three different quantum dot form factors for enhancing color saturation in LCD backlights appear in the top, middle, and bottom rows, respectively. Edge optic, film, and on-chip form factors are shown from left to right. (The on-chip photo is a WLED product representative of a QD-LED form factor since no QLED on-chip products are currently on the market).

Color Gamut

Mobile-OLED-display color performance is universally praised, and it provides a significant improvement over that of typical mobile LCDs. Several different OLED modes of operation are currently in use, and hence the color performance of mobile OLED displays, as well as TV-sized OLED displays, made by different panel makers can vary. Despite these differences, the >90% of NTSC gamut* achieved by all of them is a beautiful-to-behold improvement over LCDs using white LEDs as the backlight source.

LCDs are for the most part transmissive displays, and utilize backlights to illuminate the LCD panel to produce the image. A color-filter array is used to create the three-color primary channels that reach the viewer. QDs can be used to maximize the LCD color performance with existing filter arrays by creating spectrally narrow red and green color channels to obtain a wide color gamut and high-power efficiency from a display’s blue LEDs. Compared to conventional backlight sources, QDs offer display manufacturers the ability to reach full-gamut color by producing saturated red, green, and blue colors in the display’s backlight (Fig. 2). By creating the primaries with saturated light at the BLU level, full gamut is

realized with the best possible efficiency, thereby reducing the power needs, battery volume, and component and heat sink costs otherwise associated with these higher performing displays.

Despite the vast differences in their implementation, the end result is that today’s QD-based LCDs and OLEDs have similar color gamut and color purity, both large

improvements over conventional LCD technology. Given the trend toward more colorful standards, and the steady improvement in QD material quality (in both efficiency and bandwidth), the long-term edge (in this author’s opinion) will likely go to QD LCDs in terms of the color quality they can offer to consumers.

Fig. 2: This CIE diagram shows how Color IQ (QD Vision’s quantum dot technology) increases the range of colors that a display can show. The Color IQ gamut is essentially identical to the NTSC 1953 and Adobe RGB gamuts, while white LED shows only a portion of the sRGB standard and ~70% of the NTSC/Adobe standards.

Response Speed

OLED turn-on is a purely electronic process, and hence can be extremely fast, typically quoted in microseconds. LCD response is limited by the rotational switching of the liquid-crystal molecules, and hence is measured in milliseconds, or 1000 times slower. However, the speed and timing factors limiting viewing quality are also measured in milliseconds – many consumers are aware of their TV being specified as 60, 120, or 240 Hz, corresponding to 16, 8, and 4 msec per frame. With LCDs now capable of 240-Hz operation, the limitations of display performance are dictated far less by the overall response speed of the technology, and instead by subtle effects, such as jitter and jutter. For the average consumer, and even for the display guru, both OLED displays and LCDs offer satisfactory response speed, with any remaining limitations being more a matter of digital image processing than the display panel.

Viewing Angle

Historically, the degraded performance of transmissive LCDs when viewed from oblique angles was a major performance limiter. However, LCD technology has demonstrated a combination of new LC modes (e.g., IPS), thinner LC cell gaps, and new optical control films (e.g., WV film) that makes LCD TVs good enough for most viewing scenarios. OLED TVs may look better in the store when viewed from well off of center, similar to plasma displays, but offer little practical benefit over LCD TVs when viewed in a typical living room. Interestingly, curved TVs, should they become a trend, could accentuate this difference – which may be one of the reasons why this feature is being pushed by OLED manufacturers, with LCDs as fast-followers.

Thickness

The LED-BLU edge-lit designs that were established at the end of the last decade resulted in LCDs offering a thinness and lightness that closely approached that of OLEDs. This was a marked improvement over the CCFL-backlit TVs that were dominant in the middle of the decade, reducing thickness from a few inches to less than an inch.

Power Efficiency

The LEDs used in LCD backlights are far more efficient today than the OLED pixels themselves, but the many losses built into the LCD stack (polarizers, color filters) make the LCD system efficiency lower than the individual pixel efficiency of an OLED display. However, when comparing display systems to each other, one must also factor in the OLED power losses from their own circular polarizers, as well as resistive and capacitive losses associated with the current-driven technology. It is for these reasons that OLED mobile displays consume more power than liquid-crystal-based mobile displays, despite running at lower peak brightness. These same factors get far worse as one increases screen size and screen resolution to a point where OLED TVs on the market are consuming two or even three times that of an equivalent LCD TV. (Colegrove’s Touch Display Research, Touch and Emerging Display Monthly Report, August 2013, pp. 9–14.)

Looking forward, OLED displays have pending improvements from the roll-out of phosphorescent green emitters, and, perhaps one day, blue. However, LCD improvements are easily keeping pace with those of OLED displays, gaining efficiency every year, and with new film and materials technologies continuing to improve overall LCD light throughput.

OLED and QD Technology: Differences

The real difference between OLED and QD technology lies in how they are made. OLEDs are made from complex organic materials that are expensive to make and

purify. Manufacturing OLED displays is also an expensive and complicated vacuum production process, requiring the deposition of many layers of precisely

controlled thin films of organic molecules on a substrate, and nearly hermetic packaging of the devices.

QD materials, on the other hand, are made from abundant inorganic substances using a two-step synthesis process. The QD components can be integrated into standard LCDs with no changes required to the LCD fab infrastructure whatsoever. Incremental improvements in LCDs and the persistence of low volumes in OLED manufacturing have resulted in OLED display’s bill-of-material (BoM) being greater than that of LCDs. And that is before the significantly lower yield of OLED displays compared to LCDs is taken into account.

The argument has been made that “new” OLED manufacturing processes, such as ink-jet printing, laser transfer, nozzle jet, and OVJP, will reduce material waste and improve yields, making OLED display costs lower than that of LCDs. These arguments are now 15 years old, and still these techniques are in the R&D stage. Indeed, we first saw an ink-jet-printed OLED TV demo at Display Week in 2004, will see them again in 2014, and have yet to see a single commercial product

result, despite what is, no doubt, more than a billion dollars invested in the intervening decade.

Contrast Ratio

Contrast ratio is strongly dependent on how dark a black level a display can produce. In most LCDs, the backlight is always on, and so the black level is related to how completely the liquid crystals can block the light. This “off” state is imperfect, and so LCDs produce a perceptible glow even when attempting to show a completely “black” screen in a dark room.

OLED displays do not require backlighting to function. OLED pixels are independently lit, like tiny red, blue, and green light bulbs. To represent “black,” the pixels can be literally turned “off.” In low ambient light conditions, such as a dark room, an OLED display screen can achieve a higher contrast ratio than that of an LCD screen. This is a truly beautiful image, and today the clearest example of a quality difference between an OLED display and an LCD. However, in normal ambient light conditions for watching TV, this black state of an OLED display is difficult to achieve. The front-of-screen reflection of ambient light dominates the contrast ratio in most home-viewing experiences. In addition, there is a growing trend in LCDs toward so-called “2-D dimming” – this is a direct-lit backlight unit with separate zones that can have their brightness reduced (or eliminated) if there is no brightness in that zone of

the image. In this way, LCDs can also produce a true “off”-state black, provided the black is present not just in one pixel but in the entire dimming zone. As this technology improves, the number of zones increase and the cost and thickness are reduced; this technology may allow LCDs to neutralize even the

OLED display contrast advantage.

Hype vs. Reality

There has been a lot of excitement in the market about OLED TV, as well there should be considering the picture quality the technology can provide. But the argument that OLED display technology offers significant advantages over existing LCD technology no longer holds true, particularly since the introduction of quantum dots. Quantum dot-enhanced LCDs provide better color gamut than OLED displays and reduce power consumption, all at a minimal increase in cost over conventional LCDs.

More importantly, quantum dots are commercially available today, while, despite heavy investments in OLED displays for well over a decade, there still has been

little progress in terms of using the technology for mass-producing large-sized applications on an affordable basis, due to the manufacturing costs involved. With OLED TV not progressing as fast as hoped (estimated by DisplaySearch to be at best 100,000 units sold in 2014, in contrast to a few hundred-million mobile phone displays; NPD DisplaySearch Quarterly TV Design and Features Report, April 2014) and LCD makers needing extra features to justify UHD prices, this looks like the right time for QD full-color gamut capabilities to become a key product feature and motivator for consumer television upgrades.

Analysts are already predicting rapid growth in design wins for quantum dots in 2014, with penetration increasing rapidly in the following years. While conventional LCD TVs with white-LED backlights are dominant, and LCD TVs with quantum dot-enhanced backlights are becoming a major force already, the future of OLED TV is less certain. •

*Based on the gamut defined by the NTSC standard, an older but still widely used color TV standard developed in 1953.

Seth Coe-Sullivan is Co-founder and Chief Technology Officer of QD Vision, Inc. He can be reached at scoe-sullivan@QDVision.com.