Display Week 2013 Review: Touch Technology

Display Week 2013 Review: Touch Technology

2013 was a year of evolution and maturation for touch technology, with projected-capacitive dominating the exhibit floor like never before. This article takes a close look at the state of p-cap at the Vancouver show, as well as at the “Touch-Gesture-Motion” Market Focus Conference at Display Week.

by Geoff Walker

AS recently as only 2 years ago, there were 12 different touch technologies exhibited at Display Week1; this year, there were only four. Those were projected-capacitive (p-cap, both discrete and embedded, at 21 of the

23 exhibitors), analog and/or digital resistive (at 8 of the 23 exhibitors), electromagnetic resonance (EMR) digitizer at one exhibitor, and force-sensing at one exhibitor. That’s a big change! The main reason for the change is the expanded dominance of p-cap. According to DisplaySearch,2 in 2013 p-cap will account for 81.4% of units and 92.3% of revenue shipped. Looking at the same data for all touch technologies by commercial (traditional “vertical markets”) vs. IT/CE (information technology/consumer electronics) products, 95.0% of units and 97.0% of revenue will be IT/CE. In other words, it’s all about p-cap, and commercial and industrial applications are becoming

insignificant in the touch world.

Even with the reduced number of technologies shown, touch was still a big part

of the Display Week 2013 exhibition. The 23 exhibitors mentioned in the above paragraph include those showing

discrete touch modules, embedded touch, and controllers. In total, there were 63 touch-related exhibitors (35% of 182 total) at Display

Week 2013, as shown in Table 1 below. (Note that many of the materials exhibitors naturally serve both the display and touch markets.)

Table 1: There were 63 touch-related exhibitors at Display Week 2013; 23 (36%) showed touch modules, controllers, or embedded touch; 22 (35%) showed touch materials or related processes and technology; and 18 (29%) showed touch displays, integration, enhancements, or market research. In this analysis, each exhibiting company is counted only once, even though it could be in multiple categories.

| Product Category |

Exhibitors |

Product Category |

Exhibitors |

| Modules |

15 |

Bonding |

2 |

| Enhancements |

8 |

Glass processing |

2 |

| Adhesives |

2 |

Market research |

2 |

| Metal & CNT films |

5 |

EMR digitizer |

1 |

| Touch displays |

5 |

Haptics |

1 |

| Controllers |

3 |

Laser patterning |

1 |

| Embedded touch |

3 |

Multi-touch self-capacitive |

1 |

| Glass |

3 |

Pressure-sensing tiles |

1 |

| Integration |

3 |

Passive styli |

1 |

Embedded Touch

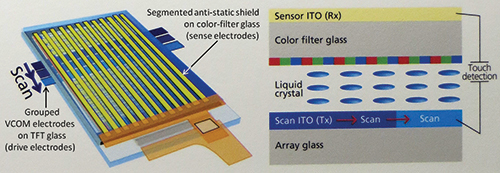

At Display Week 2012,3 embedded touch was big news with the announcement of the first high-volume shipments of hybrid in-cell/on-cell by Sony (now part of Japan Displays, Inc., or JDI). Not unexpectedly, JDI had the most extensive exhibition of embedded touch at Display Week 2013, with heavy promotion of its somewhat-misleading brand name “Pixel Eyes.” Figure 1 illustrates how Pixel Eyes is assembled, from both a physical construction and a layer perspective.

Fig. 1: JDI’s (formerly Sony’s) “Pixel Eyes” hybrid in-cell/on-cell embedded touch is shown from both a physical construction (left) and a layer perspective (right). For a more detailed explanation of how it works, see Ref. 3. Source: Artwork by JDI; annotation on left by the author.

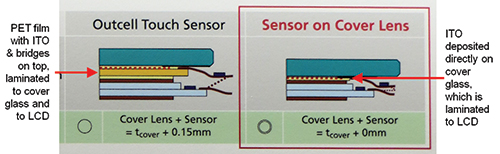

As an example of its latest innovation, JDI showed a 7-in. 2560 × 1600 (431 ppi) IPS-LCD with Pixel Eyes that was configured for use with a passive pen (only). At that pixel density, anything drawn on the screen was rendered with exquisite sharpness. The entire display was only 1.78-mm thick, including the cover glass. JDI was also showing its version of OGS (one-glass solution), which it calls “Sensor on Cover Lens” (illustrated in Fig. 2).

Fig. 2: JDI’s version of OGS (one-glass solution), called “Sensor on Cover Lens,” is compared with conventional discrete (“outcell”) touch-sensor construction. Note that the total thickness reduction gained through OGS is only 150 µm. Source: Artwork by JDI; annotation by the author.

LG Display (LGD) showed hybrid in-cell/ on-cell embedded touch in a 7-in. LCD, where the drive electrodes were on the oxide-TFT glass (the same as JDI) but the sense electrodes were on a PET film laminated between the color-filter glass and the cover glass. LGD named this configuration “F1T”, a creative modification of the current p-cap layer-construction abbreviation format. The signage shown with the display allowed an observer to calculate that 40 VCOM electrodes are grouped to form each of 32 drive electrodes. The signage also specified a minimum passive-stylus tip diameter of 2.5 mm, which is not quite as good as the typical 1.8–2.0 mm currently being specified by the top touch-controller suppliers. Unfortunately, the touch performance of the display was very erratic. The booth staff suggested that the problem was too much electromagnetic interference (EMI) at the show. If so, I look forward to better demonstrations in the future when they work this out.

The third display manufacturer showing embedded touch was Innolux. In a change of strategy from last year’s “we supply all forms of embedded touch” exhibit, Innolux this year showed only on-cell in many different displays, including a 4.5-in. 1280 × 720 (330 ppi) 2-D/3-D LCD. When questioned about this change, booth staff said that Innolux had decided to “keep LCD yields as high as possible” by building the complete cell, including glass thinning, and then adding the touch screen. This approach results in lower-quality ITO, since high-temperature annealing cannot be done on a completed cell. Innolux explained that its business priority was to keep LCD cell yields at maximum, and therefore it had to accept some performance compromises in touch implementation. This positioning was emphasized (perhaps inadvertently) by Innolux in its 39-in. touch display made with ITO in a diamond pattern at 50 Ω/sq. The ITO in this display (shown in Fig. 3) was so visible that it almost seemed to be part of the image.

Fig. 3: Innolux’s 39-in. touch display was made with ITO in a diamond patternat 50 Ω/sq. The right-hand photo is a close-up of the area outlined in red in the left-hand photo. The ITO is so visible it almost seems like part of the image. Source: Author photo.

In another change of strategy from last year’s exhibit, Innolux did not make any use of its “Touch On Display (TOD)” brand. While the company confirmed that the brand does cover all forms of embedded touch (in-cell, hybrid in-cell/on-cell, and

on-cell), booth staff said that Innolux is only using the brand “with customers.”

Projected Capacitive

Showing off its expertise in high-performance large-format p-cap, 3M Touch showed a prototype of its latest 55-in. touch-display table. It truly was a prototype; underneath the table was a standard laptop strapped to a standard NEC LCD.

AMTouch USA (part of AMT-Taiwan) showed a 21.5-in. p-cap touch display with

surprisingly good performance. In part, this performance is due to AMTouch doing its own controller firmware so

it can provide better support to commercial customers. AMTouch is not the only supplier using this strategy; another on the exhibit

floor was UICO. In UICO’s case, the primary reason for doing its own controller firmware is to optimize

for industrial-application conditions such as water and gloves. A supplier (also on the exhibit floor) taking the opposite strategy is Ocular;

instead of doing its own firmware, Ocular partners very closely with Atmel to

optimize for industrial-application conditions.

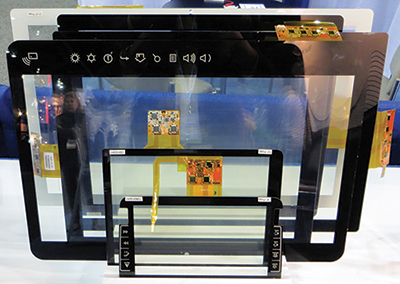

While visiting the Panjit (Mildex Optical) booth, this author was able to take a

picture of the wide variety of sensors being shown. Figure 4 shows a stack of seven Panjit p-cap touch screens. This is actually a good example of the large quantity of touch-screen hardware

that is available for close inspection on the exhibit floor.

Fig. 4: This stack includes seven Panjit (Mildex Optical) p-cap touch screens. Source: Author photo.

Other Touch Technologies

As noted in the introduction to this article, the only other technology shown in any quantity on the exhibit floor was analog and/or digital resistive. Of the eight exhibitors, the best in the author’s opinion was Fujitsu. The reason is that it was best able to clearly communicate its differentiation in terms of features as follows:

• 4-, 5-, 7-wire and “gesture-touch” types

• Pinch, rotate, flick, and swipe gestures

• 10-finger multi-touch via digital resistive

• Film-glass and film-film-plastic construction

• Very low activation force (“Feather Touch”)

• Drivers for Windows, Linux, and Android

• USB, serial, I2C, and SPI interfaces

• Gorilla glass and plastic substrates

• Anti-glare or clear finish

Instead of saying (in effect) “we sell resistive touch; everybody knows what that is,” the company painstakingly identified its advantages and engaged visitors with demos that fit the audience such as digital resistive for military applications.

There actually was one additional touch technology on the exhibit floor, but it

wasn’t identified as such. Bi-Source (BSI), a touch-display maker, used a 72-in. touch display with

traditional infrared as an attention-getter for its booth. The author is fairly sure that it was the only IR touch screen on the entire floor.

Other Interesting Bits

Touch is so well-integrated into Display Week that you really have to walk the

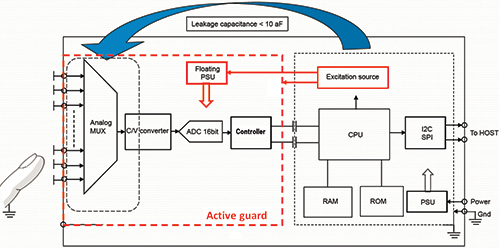

entire show in order to see everything that’s touch-related. Exhibits of particular interest included Fogale, Cima NanoTech, Canatu, and Samsung Display. Fogale, based in France and exhibiting in the Innovation Zone, was showing “multi-touch/ multi-touchless self-capacitive.” In these times of pervasive mutual-capacitive p-cap, self-capacitive is not

something that’s seen frequently. Fogale’s technology uses an “active guard” to totally eliminate all parasitic capacitance, allowing measurement of 0.0001

pF between an electrode and the target (this is 100× better than what’s possible with current technologies). This active-guard approach isolates a sense electrode (or an entire circuit)

from ground, thus eliminating the effect of the parasitic capacitance between

the sense electrode and ground. It works by applying a sinusoidal signal to the sense electrode; this allows

measurement of the current flowing through the parasitic capacitance between a

sense electrode and ground. An exactly equal signal is applied to a guard electrode that surrounds the sense

electrode. Because the sense and guard electrodes are at the same potential, the leakage

current from the sense electrode to ground is reduced to essentially zero, thus

eliminating the effect of the parasitic capacitance.

Fogale is initially focusing its technology on smartphones and tablets; it

supports five touches on a 5-in. screen and 10 touches on a 10-in. screen. When the user’s hand is hovering above the screen, Fogale supports recognition of individual

fingertips at up to 5 cm, and the whole hand at up to 8–10 cm. Accuracy and linearity are better than 1 mm. Figure 5 shows a block diagram of Fogale’s controller with a red dotted line around the portions that are isolated by the

active guard. Note that the leakage capacitance shown in the drawing is in terms of attofarads (1×10-18 farads).

Fig. 5: A block diagram of Fogale’s “multi-touch/multi-touchless self-capacitive” controller shows the components that are shielded with an “active guard” surrounded by a red dotted line. Source: Excerpted from Fogale’s Exhibitor Forum presentation.

Cima NanoTech is a relatively new entrant in the ITO-replacement materials

market; it was showing a “self-assembling silver mesh.” Cima’s material starts as an opaque liquid that’s coated on film using industry-standard equipment; 30 sec later the liquid

dries into a random-pattern silver mesh with 5-µm conductors and 150–300-µm open spaces – very similar to the characteristics of printed metal-mesh material. This product received a Best-in-Show award at Display Week.

Canatu, based in Finland and exhibiting in the Innovation Zone, was showing a

new form of carbon nanotubes (CNTs) called Carbon NanoBuds. These are yet another new transparent conductor (i.e., ITO-replacement) material consisting of carbon nanotubes with a buckyball

(fullerene) attached. Canatu claims that the addition of buckyballs to some CNTs makes the material

much more able to combine with other materials due to some buckyballs having

only five carbon atoms rather than CNT’s six-atom structure. In the author’s opinion, Canatu’s real breakthrough is its “NanoBud Reactor,” which takes transparent film and carbon gases as inputs and outputs a patterned

touch sensor made with relatively uniform length and relatively pure CNTs. Solving the problems of length and purity in a single manufacturing process is

something that the rest of the CNT industry has not been able to accomplish yet.

Finally, among many other things, Samsung Display showed a 23-in. “metal-wired touch” display with a plastic cover lens. The touch module was constructed of poly-methyl methacrylate (PMMA) with an

OCA-attached film-sensor (made of either metal mesh or silver nanowire; it wasn’t clear which). The PMMA cover glass was particularly nice, with anti-glare, a very good touch

feel, and 5H hardness. Unfortunately, the touch performance (rated for 10 touches) was not as good as

it could be; the system tended to drop touch points when 10 touches were moving

at high speed. It may have just been over specified, since the system performed acceptably with

two or three touches at moderate speed.

Summary of Observations from the Exhibit Floor

The following are the author’s observations after studying the exhibits:

• In previous years, the number of touch module-makers exhibiting usually exceeded the number of touch-materials makers; in 2013, they were roughly equal.

• At least for Display Week, p-cap has knocked out almost all other touch technologies except resistive.

• Embedded touch in all forms (in-cell, hybrid in-cell/on-cell, and on-cell) is growing.

• ITO replacements, especially metal mesh, are growing.

• Enhancements such as top-surface coatings, filters, and bonding are very important in commercial applications.

• In general, Display Week touch exhibitors tend to appeal more to commercial users than consumer users.

• Even though p-cap is overwhelmingly dominant, innovation in touch continues.

Market Focus Conference

Wednesday’s all-day “Touch-Gesture-Motion” (TGM) Market Focus conference (produced by IHS in cooperation with SID)

consisted of 23 presentations focused on next-generation touch-, gesture-, and

motion-based technologies applicable to the display industry. In the author’s experience, presentations at business/technology conferences such as this can

be classified into three groups: market or technology forecasts, product or

company pitches, and truly thought-provoking presentations that transcend

either of the first two. The first category is straightforward, usually consisting of talks by analysts

and technologists (including the author). The challenge for all speakers at business/technology conferences is to land in

the third category; the realities of marketing and business typically force

many (or most) speakers into the second category.

At this TGM conference, there were four presentations that the author found

truly thought-provoking; they were by York University, Sensor Platforms,

Elliptic Labs, and Qualcomm. Wolfgang Stuerzlinger, a professor at York University in Toronto, Canada,

presented “Is ‘Iron Man 2’ Right? Re-Investigating 3D User Interfaces.” 4 Beginning with a video clip from the movie Iron Man 2, showing superhero Tony Stark commanding a “floating-in-the-air” 3-D user-interface (UI), Wolfgang’s presentation argued that while floating objects look cool in movies, they do

not exist in reality and are therefore a poor basis for a 3-D UI. Wolfgang also showed results from several studies that measured the throughput achieved with a variety of 2-D and 3-D pointing and touch methods, with the general conclusion that as

the distance from the target increases and/or as 3-D viewing is added,

throughput goes down. In other words, it is tough to beat the good old mouse, even for manipulating

3-D objects! During his presentation, Wolfgang noted that in his opinion, the “Iron Man” trilogy should be required viewing for students of 3-D UIs (along with, of course, Minority Report) – primarily as examples of what not to do!

Kevin Shaw, CTO of Sensor Platforms, presented “Context Awareness Using Sensors.” Kevin defined context as “a framework that provides understanding of an event.” Context is transitory, multivariate, and personal; it is not a gesture or a

picture; and it must work for everyone all the time. Kevin used a number of common activities to illustrate the value of context;

these included answering the phone, going to a meeting, reaching for

toothpaste, driving home, visiting your doctor, teaching a class, and

monitoring the driving behavior of your teenage daughter. He then used the analogy of human senses and the brain to make the point that

mobile devices equipped with (a) a variety of hard and soft sensors (he showed

a list of 16), (b) sophisticated algorithms, and (c) always-on sensing (i.e., continuous measurement) can become context platforms that enable a new class of smart mobile apps. In closing, Kevin showed the power consumption of 10 common sensors that ranged

from 5 µA to 75 mA, making the point that designing for low power is the pre-eminent

challenge in achieving his vision of “context platforms.”

Tobias Dahl, the founder and CTO of Elliptic Labs, presented “Touchless Ultrasound Gestures – from Physics to Use Cases.” Tobias’s presentation explained in detail how ultrasound can be used as a rich

gesture-recognition platform technology. Tobias started with the physics of ultrasound: (a) the relatively slow speed of

sound allows accurate determination of relative motion even with low bandwidth

and only a few sensors and (b) the wide field of view created by diffraction

allows sensing movements far away and up close, with a 180° field of view. Next, describing features derived from the physics, Tobias explained that it is

easy to create a depth filter using ultrasound because ultrasound derives (x,y)

position from multiple- range (z) measurements, while stereoscopic optics

derives z from multiple correlated (x,y) positions. Finally, Tobias described nine categories of gestures that can be used with

mobile devices, and five uses cases – including how ultrasonic-sensed gestures could be used to play Angry Birds.

Francis MacDougall, Senior Director of Gesture Technology at Qualcomm, presented

“Touch-Free Gestures for Next-Gen UX.” Francis’s presentation focused on the emerging use of gestures in mainstream

consumer-electronics devices. He used, as an example, the Samsung Galaxy S4, analyzing the functionality of

its five “air gestures,” as well as the use-case for hover in five applications. Francis pointed out that hover is now available in touch controllers from

Cypress and Synaptics and that hover is a standard part of Android, implemented

seamlessly with other touch-screen event handling. Next, Francis summarized the common near- and far-field gestures in use today

and described a method of adding gestures to existing applications through the

use of a “gesture layer.” After summarizing some current and soon-to-be available hardware, Francis closed

with three pieces of advice to device-makers: (a) focus on using gestures to

enable user experiences that go beyond touch by speeding up specific tasks, (b)

rapid UI feedback for all touch-free interactions is essential, and (c) expect

higher-fidelity gestures using emerging technologies (such as ultrasound) in

the next 12 months.

The astute reader may say, “Wait a minute! The last three of those presentations sounded suspiciously like product pitches!” True, every presentation by a commercial enterprise other than market or technology forecasts are basically product or company pitches at heart. What separates the wheat from the chaff is if after a presentation I feel more knowledgeable (educated), I’m excited about future possibilities, and I find myself thinking hard about how

what I just heard fits into my view of the world.

Touch in Depth and Breadth

Once again, there was an amazing amount of touch technology at Display Week

2013. This is especially clear when one considers the additional touch resources at

Display Week beyond the exhibits, including the 13 Symposium touch papers, the

Sunday Short Course on touch, the two Monday Seminars on touch, the six

Exhibitor’s Forum touch presentations on Tuesday, the 23 presentations at Wednesday’s Market Focus “Touch-Gesture-Motion” conference, and, finally, the seven Touch and Interactivity posters presented

in Thursday’s Poster Session. It is these additional resources that differentiate Display Week from any other

touch conference worldwide. While Asian touch exhibitions such as Touch Taiwan5 (in Taipei) or C-Touch6 (in Shenzhen) may have more exhibits by touch module and material suppliers, no other conference has Display Week’s depth and breadth of presentations on touch. If you are involved in the touch industry, you just can’t afford to miss Display Week 2014 in San Diego. Start planning for it now.

References

1http://informationdisplay.org/IDArchive/2011/JulyAugust/TouchTechnology.aspx

2DisplaySearch, “Quarterly Touch Panel Market Analysis Report” Q2-2013.

3http://informationdisplay.org/IDArchive/2012/September/DisplayWeek2012ReviewTouch-Technology.aspx

4An earlier version of Professor Stuerzlinger’s presentation can be viewed as a 27-minute TEDx video at http://www.youtube.com/watch?v=3Q3Pft-xA0Y.

5http://www.touchtaiwan.com/en/

6http://www.chinaexhibition.com/Official_Site/11-3311-C-TOUCH_2013_Shenzhen_- The_

11th_China_(Shenzhen)_International_Touchscreen_Exhibition.html •

Geoff Walker is a Senior Touch Technologist at Intel. He has also been Information Display

’s Guest Editor for Touch & Interactivity since 2007. He can be contacted at geoff.walker@intel.com, 408/765-0056 (office) or 408/ 506-7556 (mobile).