2014 SID Display Industry Award Winners

Once again, The Society for Information Display’s Display Industry Awards Committee has selected six award winners that have advanced the state of the art of display products and technology in the categories of Display of the Year, Display Component of the Year, and Display Application of the Year.

Compiled by Jenny Donelan

YOU do not need to read a word of this year’s Display Industry Award descriptions to guess at a general trend – all you have to do is look at the pictures. Three of this year’s winners are curved devices. Samsung’s curved AMOLED panel forms the basis of the Galaxy Round smartphone, which is curved from side to side so it can easily fit in your hand. LG’s G Flex OLED-based smartphone is also curved, in this case from top to bottom, to fit more easily against a user’s face. LG’s OLED TV makes a curvaceous statement on a large scale – 55 in. Two of this year’s winners – Universal Display’s green phosphorescent UniversalPHOLED emitter and Canatu Oy’s Carbon NanoBud Film – are materials that support flexible and hence curved displays.

In addition, it would be wrong not to point out that four of the six winners this year are OLED based. There has been some discussion in recent months about whether OLEDs really are destined for success. Based on these products, the answer would seem to be yes. According to Display Industry Awards Chair Wei Chen, “The past year marked significant breakthroughs for OLED technology, with the commercialization of flexible OLED displays, large-sized OLED panels for TV, and the green phosphorescent emitter material, all for the first time. The 2014 SID Display Industry Awards recognize these great achievements.”

The odd product out this year is Google’s Chromebook Pixel, an LCD-based laptop with nary a curve. What it has, though, are stunning imagery and great design. Not everyone has jettisoned their laptop for a tablet or a smartphone – laptops are still where a lot of the real work gets done. Kudos to Google for taking on an everyday product category and making an extraordinary product. It’s this kind of imagination (and hard work) that make the display industry so dynamic. Research and innovation are alive and well.

Every year, the display industry continues to amaze and inspire us. Please join us in saluting this year’s Display Industry Award winners, the best of the best.

Display of the Year

This award is granted to a display product with the most significant technological advances or outstanding features.

Gold Award: Samsung Display’s 5.68-in. Curved (Flexible) AMOLED Display

The Samsung 5.68-in. FHD curved AMOLED display represents a major milestone for the entire display industry – the world’s first truly flexible full-fidelity display technology to be mass produced and adapted for use in a mass-market product. Now being produced on a plastic substrate, the new Samsung display panel enables smartphones such as the Samsung Galaxy Round to be curved, significantly improving a user’s grip.

Smartphone users will be able to comfortably hold a larger-screen version of the panel with just one hand. The smartphone has a curvature of 400 mm, while human hands have a natural curvature of about 300–500 mm. Also, the display enables a more visually immersive mobile experience with a “landscape view” aspect ratio of 1.88:1, comparable to the Vista Vision technology (1:83:1) now used in most movie theaters. In addition, the curved screen is more readable thanks to a significant reduction in light reflectance. Samsung’s new curved display will later

evolve into bendable and foldable displays that will further revolutionize the use of smartphones and other mobile-product form factors.

The Samsung 5.68-in. FHD flexible display used in the Galaxy Round is fabricated on a special type of plastic that is capable of withstanding high processing

temperatures to ensure adequate mobility, Vth, and other TFT characteristics. The plastic substrate is fabricated on carrier glass, and after TFT processing and organic material deposition, the substrate is removed from the carrier glass using a proprietary liftoff process.

Silver Award: LG Display’s 55-in. FHD Curved OLED TV Panel

LG’s curved OLED TV was introduced last year, bringing a new kind of viewing experience into the home. The TV uses LG’s WRGB OLED technology with an oxide TFT backplane, the company’s technical solution of choice for large-sized OLED panels. The panel is slim – only 4 mm thick with side bezel widths of 11 mm. At 19.2 pounds, the TV is also substantially lighter than competitive products. At the same time, it offers superior picture quality, achieving remarkably rich and natural colors through 8.3 million subpixels with the addition of white subpixels – 2 million more subpixels than competitive panels. The panel also delivers clear images with less than a 0.001-msec response time, 5,000 times faster than most LCDs. Most notably, LG Display’s curved OLED TV panel can realize deep and dark blacks with the capability of reproducing a wide spectrum of blacks, allowing for an optimal contrast ratio.

In addition to the vivid and enhanced picture-quality experience, the curved structure of the new OLED TV panel offers viewing comfort. The curvature mimics a human’s normal line of vision, known as the “horopter line,” which makes it more eye friendly and allows viewers to feel less fatigue even when watching the screen for long periods of time. Users will also enjoy a more theater-like viewing experience because the curved screen has a wider and brighter field of view. The IMAX-like curvature of the screen minimizes visual distortion and loss of detail. LG Display’s curved OLED TV panel also incorporates the company’s acclaimed FPR 3-D viewing technology, which minimizes eye and body muscle strain during 3-D viewing. The added FPR 3-D film on the curved OLED TV panel offers better depth as well as a clearer 3-D effect.

|

DISPLAY OF THE YEAR

|

|

|

|

|

Gold Award: Samsung’s curved and flexible OLED panel has been incorporated into the company’s Galaxy Round smartphone.

|

Silver Award: LG’s 55-in. FHD curved OLED TV panel offers exceptionally vibrant imagery in a

curved format that offers viewers a comfortably immersive environment.

|

Display Component of the Year

This award is granted for a novel component that has significantly enhanced the performance of a display. A component is sold as a separate part destined to be incorporated into a display. A component may also include display-enhancing materials and/or parts fabricated with new processes.

Gold Award: UDC’s Green Phosphorescent UniversalPHOLED Emitter Material

OLED displays gained a large energy efficiency boost in 2013 when Universal Display Corporation (UDC) began shipping commercial green UniversalPHOLED emitters to panel makers for incorporation into mobile products. UDC’s proprietary green phosphorescent OLED (PHOLED) emissive system can reduce an OLED display’s power consumption by approximately 25%, while providing excellent color in mobile displays. Adding green PHOLEDs to displays has increased OLED’s competitiveness with LCDs for mobile applications, and this new material is expected to be a key driver in the commercialization of OLED TVs.

Through years of R&D work and achievements, UDC has produced UniversalPHOLED materials that provide record-breaking energy efficiencies, vibrant colors, long operating lifetimes, and manufacturing versatility. The green PHOLED emitter builds on the successful commercialization of UDC’s red UniversalPHOLED emitter, first launched in commercial passive-matrix display products in 2003. PHOLED materials are expected to drive wider adoption of OLED technology and greater growth in the display and lighting markets because they significantly reduce power consumption and lower heat emission compared to prior fluorescent green OLED materials. Based on these advantages, UDC believes that all OLED products, including smartphones, tablets, TVs, and lighting panels, will benefit from the use of its green UniversalPHOLED materials.

Silver Award: Canatu Oy’s Carbon NanoBud (CNB) Film

Canatu Oy’s Carbon NanoBud (CNB) Film provides superior optical performance for flat, flexible, or formable touch screens, displays, and touch-sensitive surfaces. This transparent conductive film is used in capacitive touch sensors for portable devices such as mobile phones, tablets, and digital cameras, and in automobiles that require excellent display readability in outdoor and bright indoor environments. With near-zero reflectance (less than 0.2%) from the CNB touch layers, CNB touch sensors improve contrast by up to 40%, and thus enhance display readability compared to incumbent touch solutions. In portable applications, the high contrast further enables the use of lower backlight power to increase battery life by up to 20%. CNB films have the highest transmission of any carbon nanomaterials, with 96%

transmission at a 150-Ω/□ sheet resistivity, practically zero haze, and almost perfect color neutrality.

CNB films are also applied in capacitive touch sensors for flexible wearable devices such as smart watches and flexible and foldable mobile phones and tablets. The films are highly foldable down to a bending radius less than 1 mm over more than 100,000 bending cycles. Another application of CNB films is in 3-D formed capacitive-touch surfaces in smart watches, home-appliance control panels, automobile center consoles and dashboards, and mobile phones. The films and sensors are stretchable up to 100% (twice their linear dimension) and can be thermoformed and overmolded with standard industrial processes such as film insert molding or in-mold

decoration.

Carbon NanoBud material is made from carbon nanotubes and fullerenes. Being carbon based, it absorbs light as opposed to reflecting as with commonly

used ITO and other transparent conductive materials such as silver nanowires and metal meshes. This is the reason why CNB sensor layers have almost zero (<0.1%) haze and almost zero (<0.2%) diffuse and specular reflectance. When deposited on a substrate, CNB material forms a random network that is highly flexible and stretchable. Canatu’s CNB manufacturing process is environmentally friendly and cost effective, with CNB film produced from common carbon gases in a single process step at room temperature, on rigid or flexible substrates, and in sheet or roll-to-roll form.

|

DISPLAY COMPONENT OF THE YEAR

|

|

|

|

|

Gold Award: UDC’s green phosphorescent UniversalPHOLED emitter material is designed to reduce an

OLED device’s power consumption while providing excellent color.

|

Silver Award: Canatu Oy’s Carbon NanoBud (CNB) Film, made from carbon nanotubes and fullerenes, provides superior optical performance for flat,

flexible, and formable touch screens and displays.

|

Display Application of the Year

This award is granted for a novel and outstanding application of a display, where the display itself is not necessarily a new device.

Gold Award: LG Display’s G Flex

LG Display’s G Flex smartphone incorporates a flexible OLED panel that is based on a plastic substrate instead of glass. By applying film-type encapsulation technology and attaching the protection film to the back of the panel, LG Display made the panel bendable and unbreakable.

Compared to an OLED display panel based on glass, the flexible OLED panel is light-weight, thin, unbreakable, and features design flexibility. This allows for a design that naturally fits the contour of a smartphone user’s face. The G Flex’s OLED panel is vertically concave from top to bottom with a radius of 700 mm and only 0.44 mm thin. What’s more, the panel is also the world’s lightest, weighing a mere 7.2 g even with a 6-in. screen, the largest among current smartphone OLED displays.

Plastic OLED panels are made in a process similar to that of glass OLED panels; however, the former uses a plastic substrate and a different “sealing” material. First, an organic matter called Polyimide (PI) is coated on the glass substrate. A proprietary, specially developed form of multi-layered organic and inorganic film is used to encapsulate the OLEDs and protect them from moisture. In the final process, to achieve flexibility, it is necessary to separate the

glass and PI layer to remove the glass from the lower board, which can be achieved by applying a special layer. The board is naturally weaker once the glass is removed, so the back plate is then attached to the part where the glass was removed to ensure sturdiness.

In the future, LG plans to make this process applicable to the production of large-sized devices, including personal laptops, monitors, and televisions, as well as eReaders and more.

Silver Award: Google’s Chromebook Pixel

Chromebooks are built for the way that people use computers and the Web today. They make computing faster, simpler, and more secure – for everyone. The LCD on the Chromebook Pixel is stunning, providing users with a rich, immersive experience. The 12.85-in. touch screen had, at launch, the highest pixel density of any laptop (239 ppi), and the 3:2 photographic format is specifically designed for using the Web (reducing the need for scrolling). Other statistics include a maximum brightness of 400 nits, a 60% color gamut,* a wide (178°) viewing angle with IPS technology, and a 0.55-mm layer of touch-enabled glass fused directly to the screen (to preserve picture clarity). For users, text is crisp, colors are vivid, touch interactions are smooth – and each of the 4.3 million pixels seems to disappear into one spectacular picture.

Google used a-Si TFT technology for the pixel to reduce the cost of the glass panel. The transmissivity of its high-ppi a-Si TFT panel was lower than panels

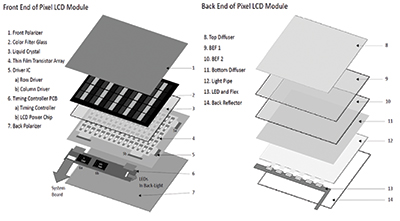

fabricated with oxide transistors or low-temperature polysilicon. To attain low power consumption using a-Si, the company optimized the remaining components (including LEDs, optical films, and light pipe). The stack-ups can be seen in Fig. 1.

Fig. 1: At left is shown the stack-up of the Pixel LCD module’s front end. At right is the stack-up of the module’s back end.

The company’s goal is to continue to push the laptop experience forward, working with its entire ecosystem of partners to build the next generation of Chrome OS devices.

*Based on the gamut defined by the NTSC standard, a color TV standard developed in 1953. •

|

DISPLAY APPLICATION OF THE YEAR

|

|

|

|

|

Gold Award: LG Display’s G Flex (left/top) is based on a flexible plastic OLED display (right/bottom).

|

Silver Award: Google’s Chromebook Pixel features an LCD panel with 239 ppi.

|

Jenny Donelan is the Managing Editor of Information Display

Magazine. She can be reached at jdonelan@pcm411.com.