Display Week 2012 Review: OLEDs

55 in., 3-D, dual view, flexible IGZO, a-Si, and more.

by Sung Kim and Barry Young

SOCIETY for Information Display (SID) members and others showed up en masse to view the world's most advanced AMOLED displays at the 49th Annual Display Week in Boston. We were surprised to hear at least one well-known financial analyst report that aside from the large AMOLED 3-D TVs, there were no unexpected AMOLED developments at the show. Perhaps the display industry has progressed so far and so quickly that people expect a major technology shift every year. In fact, there was much that was notable at the show, including new backplane technologies, the demonstration of large AMOLEDs with a-Si backplanes, and flexible displays nearing mass production – all far from ho hum developments.

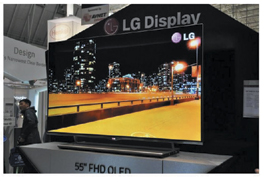

Ever since CES in January, Samsung and LG have been getting rave reviews for their 55-in. AMOLED TVs, and now we know why. The TVs shown at Display Week were thin, with high contrast, viewability from any angle, and no ghosting. Samsung showed three TVs – a 2-D version, a 3-D version, and a dual-view version (Fig. 1). LG showed only a 3-D version, but it appears that the LG unit is closer to mass production (Fig. 2).

Fig. 2: LG's OLED TV displayed vibrant imagery (left) in an ultra-thin (0.157-in.) package (right). Photo courtesy LG/OLED-A.

Although the TVs from both companies were 55 in. on the diagonal, had full-HD resolution, and used organic fluorescent and phosphorescent materials, they were constructed very differently, as shown in Table 1. From an image perspective, most people I spoke with thought they were both terrific, with Samsung having a slight edge. Perhaps the difference was the mura on the LG AMOLED, which seemed to be caused by the lack of temporal stability, a characteristic of indium-gallium-zinc-cxide (IGZO) TFTs (seeTable 1). Samsung and LG had hoped to be in production in time for the Olympics, but that is not happening. Forecasts by both companies that volume could reach 200,000 units each by the end of 2012 have been toned down to approximately 25,000 each.

Table 1: Comparative specifications for LG and Samsung OLED TVs are shown above. Courtesy OLED-A, Companies.

| |

LG Display |

Samsung Display Co. |

| Manufacturing |

Gen 8 6-up |

Gen 5.5 2-up |

| Backplane |

IGZO |

poly-Si |

| OLED Architecture |

Bottom emission |

Bottom emission |

| Stack |

Tandem |

Single |

| Color |

Yellow/orange, blue |

Red, green, blue |

| Patterning |

None |

LITI |

| Color Filter |

Yes |

No |

| Cover |

Glass/metal |

Metal |

| Comparison Material Cost |

4-light emitting |

3-light emitting |

| OLED Yield |

Medium |

High |

| Transport Yield |

Medium |

Medium |

| Backplane Yield |

Low |

High |

| Material Utilization |

Low |

Low |

| Lifetime |

Higher |

Lower |

| Gray Scale |

White plus |

3 colors |

| Driving Voltage |

2X |

X |

| Cathode |

LiF, Al+ |

LiF, Al+ |

| Power Consumption |

Higher |

Lower |

| Differences |

Effect of color filter |

Gray scales |

| Cost Comparison |

Color filter on array |

LTPS |

| Organics |

4 LELs |

3 LELs |

| Generation |

_ Gen 8 |

_ Gen 5.5 |

IGNIS Innovation, now operating out of both Canada and Taiwan, showed the world's first 20-in. AMOLED TV with an a-Si backplane(Fig. 3). IGNIS has developed technology that not only compensates for the threshold-voltage shift of the TFT but also the aging of the OLED. For a-Si, IGNIS has designed a more robust process. Some of these developments were discussed in a paper from IGNIS given at the Display Week Symposium, "Stabilized AMOLED Displays by Process Tuning and Backplane OLED Compensation." IGNIS will soon be releasing its first AMOLED product, a 3.5-in. HVGA display on a cell purchased from E Ink, propagated by a color OLED from RiTdisplay.

Fig. 3: IGNIS has introduced a 20-in. AMOLED with an a-Si backplane. Photo courtesy IGNIS/OLED-A.

Another innovative AMOLED was a 7.4-in. VGA flexible (conformable) display from the Flexible Display Center at Arizona State (Fig. 4). While the display is still in development, the University was able to demonstrate the results of an intensive program that uses a unique bond/debond process, IGZO, and a reusable carrier to produce the backplane. The cover process involved thin film and the OLED deposition and patterning of side-by-side RGB using VTE and FMM. The module process was fairly rudimentary, so there were lots of unattached rows and columns. Nonetheless, this technology demonstrator was a major achievement and a significant step in showing the practicality of flexible AMOLEDs. This OLED panel was developed with funding from the U.S. Army, features 480 x 360 (81 ppi) resolution, has an oxide-TFT (IGZO) backplane, and is built on a PEN (polyethylene naphthalate) substrate. It was developed in collaboration with Universal Display Corp., DuPont (Teijin Films), Sunic, and Henkel.

Fig. 4: Arizona State's 7.4-in. flexible OLED was one of the more impressive prototypes shown at the exhibit. Photo courtesy Arizona State University/OLED-A.

Chimei Innolux (CMI) showed up at Display Week for the first time with its pre-release small-to-medium displays that included 3.4- and 4.3-in. AMOLED panels (one shown in Fig. 5). A few days before Display Week, CMI announced that it will begin to produce these panels by Q4 2012. At the show we learned that the first OLED fab to go online is actually an old TPO/Toppoly Gen 3.5 fab. The panels will use LTPS backplanes and will both feature 960 x 540 resolution (translating to 324 ppi on the 3.4-in. panel and 256 ppi on the 4.3-in. panel). CMI says that its technology is "ready" for 4.5-in. 720p (326 ppi) panels as well. CMI uses white OLEDs with a color filter, so processes are not limited by the use of a fine metal mask.

Fig. 5: Chimei Innolux's 3.4-in panel is one of two AMOLED displays the company says will enter production in Q4 2012. Photo courtesy Chimei Innolux/OLED-A.

Samsung Mobile Display (now Samsung Display Co.; see Industry News article in this issue) also showed a range of small-to-medium AMOLED displays for the Galaxy S2 and 3, Galaxy Note, and the first AMOLED tablet. The sizes were 4.3, 4.65, 4.8, 5.3, and 7.7 in., respectively. Samsung has now fully adopted the PenTile technology for its high-pixel-density (>250 ppi) panels. For OLEDs, the PenTile approach maintains brightness, which results in an increase in lifetime. At >250 ppi, it is indistinguishable from side-by-side designs for all but the advanced image experts such as DisplayMate. Joel Pollack, Senior Vice President for PenTile developer Nouvoyance Inc., says, "PenTile technology is now used in 100% of production products with OLED displays of greater than 230 ppi. Products using PenTile OLEDs have won an SID DYA Gold Award 2 consecutive years (Samsung Galaxy S and Galaxy Note). With the unprecedented adoption by consumers of the new Galaxy S3 with a 4.8-in. PenTile OLED, it seems that the market has voted with their wallets for phones with PenTile OLED displays."

Speaking of no-shows, Sharp made a major announcement the week before Display Week that indicated the company was reversing its no-OLED policy, and revealed a 13.4-in. and a flexible OLED using IGZO. One of the OLED news sites picked up the announcement and reported that the displays would be shown at Display Week. But most of the people in the Sharp booth had no clue that Sharp had even reversed its policy and there were no OLED displays. Too bad, as Sharp had a major opportunity to make news by demonstrating why it has reversed course so dramatically. Could it be that the Hon Hai, Sharp, and Apple relationship was just too new to announce that Apple now has a supplier, not named Samsung, which is capable of providing flexible AMOLEDs?

Both eMagin Corp. and Fraunhofer IPMS showed up with OLED microdisplays, which keep improving from both a resolution and a power-consumption perspective. With the backlight eliminated, OLED microdisplays are the most efficient near-to-eye products currently available and are getting a lot of play in the area of futuristic integrated displays and glasses. The eMagin display had WUXGA (1920 x 1200) resolution with additional rows and columns that brought the total pixel count up to 1944 x 1224. The extra rows and columns allow the image to be shifted in 1-pixel increments for optical centering of the image. The full-color imager uses eMagin XL technology: a white OLED with a color-filter array. Subpixels were 3.2 μm x 9.6 μm to produce a 9.6-μm-square full-color pixel with a fill factor of 71%. The Fraunhofer IPMS HMD was only VGA, but the unit used the Fraunhofer bidirectional OLED backplane. The bidirectional OLED has a backplane that acts as both a micro- display and a camera sensor to allow eye tracking in HMDs. The microdisplay has one camera pixel for every OLED pixel. (This technology won a Best-in-Show award this year; see the Best-in-Show article in this issue.)

A number of Chinese display manufacturers have announced the goal of building AMOLEDs using LTPS and VTE, but only Tianma actually showed up at Display Week with a demo, a 12.1-in. WVGA panel that looked good (Fig. 6). Tianma doesn't expect to commercialize the demo, as it intends to concentrate on smartphone applications 5-in. and below. Tianma will install a Gen 5.5 LTPS fab for LCDs this year and hopes to convert it to AMOLEDs by the end of 2013.

Fig. 6: Tianma showed a 12.1-in. WVGA prototype. Photo courtesy Tianma/OLED-A.

Clearly, important developments in OLED technology were shown at Display Week. As mentioned earlier, perhaps the media and financial analysts have been so spoiled or are a little jaded by the pace of change that they are no longer easily impressed. What has to happen to excite these individuals; something like turning wallpaper into displays at no cost? •

Sungeun Kim is an Associate of the OLED Association (www.oled-a.org). She can be reached at sungeun@oled-a.org. Barry Youngis Managing Associate of the OLED Associa-tion. He can be reached at barry@oled-a.org. The contact number for both authors is 1-512-785-1888 .