Enhancing Mobility through Display Innovation

As consumers become increasingly reliant on mobile devices with large displays and computer-like functionality, device designers need to address limitations in both power and visibility across all lighting environments. Micoelectromechanical systems (MEMS) technology is a promising solution.

by Jim Cathey

MOBILITY – whether in the form of a smartphone, a netbook, or an e-reader – has become an integral part of many consumers' professional and personal lives. And as the literal window to the mobile world, the display plays a central role in consumers' mobile experiences, shaping their interactions with content ranging from GPS to Web browsing. However, limited battery life and poor screen visibility in outdoor lighting conditions currently stand in the way of a truly mobile experience. Emerging reflective- display technologies have the power to disrupt the current order and take consumers' mobile lifestyles to the next level.

Modern Mobile Lifestyles

Today's mobile-device designers face un-precedented opportunities: handsets have evolved from primarily voice-driven devices to highly visual platforms for multimedia and new mobile categories such as netbooks and e-readers are quickly gaining momentum. The mobile industry is seeing a proliferation of new applications and functions that – whether essential or trivial – are being quickly absorbed into consumers' mobile lifestyles.

The industry has also reached a critical juncture: in order for mobile innovation to continue along its current trajectory and satisfy consumer appetite, hardware technology must keep up with the spike in mobile functionality and consumers' increased usage. Today's mobile users face two key limitations in terms of the display: inadequate battery life and inconsistent screen visibility across varied lighting environments. (From a network point of view, bandwidth is also a problem; see "The Approach of 4G," also in this issue.) Consequently, consumers have had to adapt their behavior to accommodate power and readability limitations that dictate how, where, and when they can interact with their mobile devices.

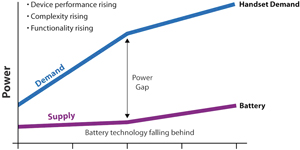

Fig. 1: It is well understood that as handset energy demands increase faster than battery longevity, the "power gap" between the two will widen.

Today's designers are consequently tasked with balancing the demand for feature-rich mobile products with device capabilities to support such functions. And given consumers' fixation with style – as evidenced by the popularity of Apple's iPhone – designers need to achieve this balance without compromising aesthetics or straying from small, sleek devices. Identifying solutions that address both power and visibility issues while enabling the appearance consumers demand is key to enhancing the functionality of the mobile products of today and tomorrow and surpassing consumers' expectations.

Demanding More from Displays

In the search for a hardware solution that addresses both power consumption and screen visibility, designers need look no further than the display. As the mobile phone has evolved, the display has taken on an increasingly vital role in the consumer's mobile experience as the literal window to the mobile world. Consequently, the spike in usage of sophisticated, multimedia-rich mobile functions has placed unprecedented demand on the display, which in the current marketplace has become the chief offender with respect to draining battery life and offering poor outdoor visibility. Consumers have adapted behaviors such as reducing usage of power-draining functions to lengthen battery life, relying on power cords and outlets to make it through the day, and shielding their devices and squinting in bright sunlight.

With today's dominant mobile-display technology – liquid-crystal-display (LCD) technology – these attempts to compensate are essential. While the LCD delivers a bright, sharp display experience in dimmer lighting conditions, the image quality deteriorates noticeably outdoors, particularly in direct sunlight. And because the technology relies on an energy-demanding backlight, the LCD is a significant consumer of a device's available power, especially when multimedia-rich applications are in use.

The Mobile-Device Power Gap

LCD technology is today's most ubiquitous display technology, and the LCD is one of the most energy-hungry of all typical mobile components. This is because the LCD polarizer limits the amount of light reflected or transmitted, so that at least 50% of available light is discarded. Due to additional layers such as color filters, the display transmits only 6% of the ambient light. Consequently, a significant amount of backlight power is required to achieve the bright visual experience today's consumers have become accustomed to.

The power drain brought about by the LCD has only recently become a significant pain point for consumers. Before the incorporation of multimedia-rich functions into our mobile lifestyles, handset performance was gauged in large part by reception quality and talk time. In many ways, the handset has transformed from a device that consumers talk into to one that they experience visually through functions such as video, Web browsing, gaming, and GPS. The power gap between consumer demand for mobile functions and handset capabilities continues to widen (see Fig. 1) as usage of these functions outpaces advances in small-form/high-power-generating battery technologies such as lithium ion cells. Consequently, the LCD's power needs force consumers to limit their displays' "on" time or remain tied to power cords and outlets.

This is not meant to discount the progress being made in the battery sector, but rather to underscore the importance of supplementing battery technology advancements with other more immediate energy solutions that address the widening power gap. The industry needs to focus on reducing energy consumption on the demand side through hardware solutions that enable continued innovation without forcing consumers to limit their mobile behavior. And, of course, it should be acknowledged that the companies that produce LCDs are also looking into ways of becoming more energy efficient. For an early look at a low-power reflective LCD technology for mobile phones, see, "Making a Mobile Display Using Polarizer-Free Reflective LCDs and Ultra-Low-power Driving Technology," also in this issue.

Metrics for Real-World Visibility

In addition to adapting behavior around power cords and outlets, mobile users have grown used to shielding their devices or searching for dark corners of shade when outdoors. As mobile devices – handsets, MP3s, e-readers, and products yet to be invented – become increasingly integral to consumers' professional and personal lives, viewability across a broad range of lighting environments will match battery lifetime as a pivotal concern.

Current metrics are divorced from what the human eye is capable of perceiving; they are based on contrast ratio, color gamut, and bit depth, which, while helpful, do not provide a real-world indication of a display's performance. Contrast ratio and color gamut are both gauged in testing labs in dark-room conditions to generate consistent and favorable results; however, both of these measurements change significantly as the display operates in a more typical real-world environment. Furthermore, bit depth is technically not a visual characteristic of the display, but rather a specification of the device's electric circuitry. Consumers in the market for a mobile device are without an accurate description of how the display will perform outside of a dark room, whether in the office, car, or outdoors. The International Committee for Display Metrology (ICDM – www.sid-icdm.org) is currently working on some very precise methods for measurement of display contrast and color under ambient conditions, with the aim of making them easy to implement and very repeatable.

Mobile Color Depth (MCD) is a set of metrics developed by Qualcomm MEMS Technologies (QMT) that is based on display performance in real-world conditions using the vision-science concept of a just-noticeable difference (JND), a measurement of what viewers can and cannot discriminate in an image. MCD bridges the disparity between today's display specifications (addressable levels) and actual visual experience (perceptible levels) by describing the number of perceived colors generated by a display in a specific viewing environment. A detailed overview of MCD methodology can be found at http://www.mirasoldisplays.com/ mcd/.

MCD has been designed as a resource for consumers at the point of sale, enabling them to make purchasing decisions based on metrics that convey how the display will perform in their day-to-day lives, rather than on numbers measured by technicians in dark rooms. It also serves as a tool for the entire mobile-device value chain, helping various players to more accurately select their display experience. When designers take into account environments in which consumers will interact with the display, product managers will be able to select features and applications accordingly and carriers will anticipate greater available revenue time (ART) from devices that can be fully utilized irrespective of lighting conditions.

Emerging Reflective Displays

Display technologies of the future need to address both the widening power gap and consumers' need to interact with their devices in a variety of lighting environments.

ABI Research underscored the demand for improved display performance in a report released in January, 2009: "Emerging Displays in Mobile Handsets." The report explains that the LCD "is still king" in the mobile-display landscape, but then identifies three emerging challengers to its throne. In addition to organic light-emitting diodes (OLEDs), ABI Research names two reflective- display technologies as the leading contenders: e-ink, the "electronic paper" display used in Amazon's Kindle, and the mirasol display from QMT. While LCD technology has improved significantly since its inception, ABI Research explains that these new reflective displays excel where LCDs falls short; namely, power consumption and visibility in bright lighting conditions.1

Reflective-display technologies have been slow to find success in commercial devices but are now gaining traction thanks to their significant impact on both power consumption and screen viewability. The reflective e-ink display has been incorporated in numerous e-readers in addition to Amazon's Kindle. Due to its reflective nature, the e-ink display draws minimal power and can be designed to mimic ordinary ink on paper for maximum readability, making it well-suited for e-reader functions.

An electrophoretic display, such as that used by E Ink Corp., is capable of holding a stable image without constant need of refresh and reflects light rather than emitting it. These attributes contribute to enhanced energy efficiency and visibility in direct sunlight.2Current generations of electrophoretic displays are suitable for imagery that changes relatively slowly and infrequently, such as eBook readers, rather than full-motion video. So, while electrophoretic technology is indeed an exciting new technology, its application to mobile devices is currently somewhat limited.

MEMS Displays

Also in the reflective category as noted by ABI Research is QMT's Interferometric Modulation (IMOD) based technology: the mirasol display. Microelectromechanical systems (MEMS) technology has existed for about the last 30 years and has more recently formed the basis for mirasol technology. QMT engineers developed the mirasol display by studying and mimicking processes and structures in nature. The most brilliant colors that occur naturally are brought about by optical interference within minute biological structures. Such interference results in "iridescent" colors that can represent any portion of the rainbow and change based on viewing angle. There are many examples of iridescent color in nature, including mother of pearl, peacock feathers, the scales of some beetles, and the wings of a butterfly.

The wings of certain butterflies have tiny scales and ridges that reflect light in such a way that only certain colors are perceptible to the eye. This is essentially the same principle employed in mirasol displays: the butterfly's wing structure, with its multitude of layers and imperfect ridges, were what the early designs of the IMOD-based product mimicked. However, engineers then discovered that by precisely controlling the thickness of the reflective layers in the mirasol display, only two layers were necessary in order to create iridescent color in the same manner as the multiple layers of a butterfly's wings.

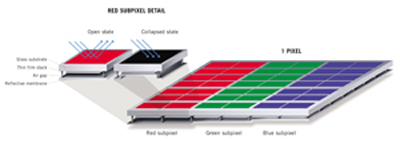

The mirasol display uses a combination of MEMS mirrors and thin-film fabrication technologies common in the flat-panel and semiconductor industries to create a spectrum of colors by reflecting light so that specific wavelengths interfere with each other to select the emitted colors. When ambient light hits the structure, the light is reflected both from a thin-film stack and off the reflective MEMS mirrors. Depending on the height of the optical cavity between these two layers, light of certain wavelengths reflecting off the mirrors will be out of phase with the light reflecting off the thin-film structure and other wavelengths will be in phase. Based on the phase difference, some wavelengths will constructively interfere, while others will destructively interfere. Figure 2 shows the layers involved in a mirasol display.

This design not only produces vibrant colors, but also inherently has low power requirements and sunlight viewability. The display's bistable nature allows for near-zero power usage in situations where the display image is unchanged, resulting in considerable power savings compared to displays that continually refresh or require a constant charge to each pixel. The power currently used for backlights can be reallocated to support functions and applications, reducing total device power consumption by 40% when compared to conventional LCDs.3 Furthermore, the mirasol display has a rapid refresh rate, making it suited for multimedia-rich applications such as video. Power savings combined with video-rate capabilities enable consumers to enjoy multimedia-rich functions without concern for battery life, and carriers in turn benefit from an increase in ART. Contrast and readability also remain across a broad range of lighting conditions, including direct sunlight, with no need for a backlight.

Commercializing an Emerging Technology

Given the above performance benefits, why isn't the mirasol display ubiquitous in today's mobile products? It's important to keep in mind that this is an emerging technology – in its relatively short lifespan, the mirasol display has already seen significant traction with three products in the marketplace and the launch of a dedicated color-mirasol fabrication plant.

Fig. 2: The color of each IMOD substrate is determined by the size of the gap between the layers.

The aforementioned ABI Research report identifies two primary hurdles facing the mirasol display and any other emerging display technology: volume and cost. LCD technology is a mature technology with manufacturing infrastructure in place, so its comparatively low cost gives it an advantage over contending technologies.1 The ability to produce in volume is the first step toward lowering cost, and consequently both e-ink and mirasol displays have made significant strides towards this end. In June 2009, Prime View International (PVI) signed an agreement to acquire E Ink Corp. for $215 million, a deal which is expected to close in the fourth quarter of 2009.4 The acquisition should shore up the manufacturing capabilities for e-ink technology.

QMT also reached a major milestone in June 2009: the opening of a dedicated mirasol-display fabrication plant in the Longtan Science Park in Taoyuan, Taiwan. The facility represents a strategic collaboration with Cheng Uei Precision Industry Co. Ltd., (Foxlink), a leading manufacturer of communications devices, computers, and consumer electronics. QMT will utilize its process-engineering expertise from dedicated teams in Taiwan and the Qualcomm MEMS Research and Innovation Center (MRIC) laboratory in San Jose, California, and Foxlink will play an integral role in the operation of the mirasol fabrication facility. The dedicated fabrication plant will enable greater volume and faster time to market.

Mobile Devices of the Future

The mobile landscape is shifting – consumers are becoming increasingly reliant on mobile devices for their professional and personal lives, and in order to maximize how, where, and when they can interact with these products, designers will need to address both the power gap and the need for functionality across all lighting environments. Future display technologies should free consumers from power cords and allow them to quite literally emerge from the shadows and experience mobility on their terms. The mirasol display is an emerging technology with significant milestones ahead, but as it continues to mature, it will open the door for designers to create products and markets that do not yet exist due to power and visibility limitations.

References

1ABI Research, "LCD Still Rules Handset Displays, But New Technologies Hunt for Niches," January 5, 2009; http://www. abiresearch.com/press/1339-LCD+Still+ Rules+Handset+Displays,+But+New+Technologies+Hunt+for+Niches.

2"E ink Technology: How It Works," http://www.eink.com/technology/howitworks. html.

3Qualcomm Labs research,

4Business Wire, "Prime View International Reaches Agreement to Acquire E Ink," June 1, 2009; http://www.businesswire.com/ portal/site/home/permalink/?ndmViewId=news_view&newsId=20090601005656&newsLang=en. •

Jim Cathey is VP of Business Development for Qualcomm MEMS Technologies (QMT). He can be reached at 858/651-6276.