Adaptive Backlight Dimming for LCD Systems

Dimming technology has evolved dramatically over the last several years and is now enabling innovations in many LCD-based products such as TVs and monitors, which must continue to improve in terms of picture quality and energy efficiency while remaining cost effective. Although dimming is valuable for both CCFL and LED backlighting applications, it can be used most effectively with LED light sources. This article also discusses some innovative edge-lighting dimming solutions.

by Pierre de Greef, Hendriek Groot Hulze, and Jurgen Hoppenbrouwers

ONLY 5 YEARS AGO, consumer LCD TV represented a brand-new technology; today, 75% of all TV sets sold use liquid-crystal displays (LCDs). This mainstream technology is still maturing in terms of picture quality, cost structure, and power efficiency. The power consumption of display applications is highly impacted by the energy consumed by the LCD module, and more than 80% of this energy is consumed by the backlight in order to achieve the required luminance. This article examines the range of backligh1 technologies.

LCD-Panel Overview

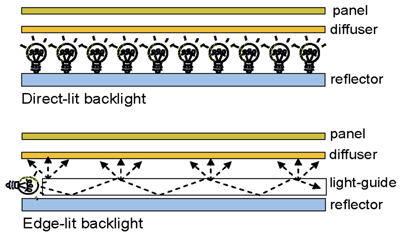

LCD-TV systems must render video and multimedia images with optimal front-of-screen performance. They also must meet many other minimum performance expectations such as contrast, luminance, color fidelity, lack of flicker, minimum viewing angle, power efficiency, and cost effectiveness. All of the above are greatly affected by the functionality of the backlight. A backlight typically comprises multiple cold-cathode fluorescent lamps (CCFLs) or white LEDs. As shown in Fig. 1, the lamps can be mounted on the edge (edge-lit) of or behind (direct-lit) the LCD panel. A stack of optical filters ensures that the light from the lamps uniformly illuminates the LCD panel, thus enabling high-quality image. Lastly, the white light from the backlight is filtered by red, green, and blue (RGB) subpixels to enable the generation of colored images on the display.

Fig. 1: Cross-sections of LCD modules show direct-lit backlighting (top) and edge-lighting (bottom).

This basic LCD-panel design has consequences in terms of energy efficiency. For example, the expected minimum luminance for TV applications is at least 500 cd/m2; monitor applications need at least 300 cd/m2. Yet, to enable this amount of light output, much more light needs to be generated. On average, only 1% of backlight luminance exits a display module because there is

• an 85% loss in light output to create images using the LC cell shutter

• a 70% loss in color filters to enable the colors

• a 50% loss in polarizers to enable light modulation by the LC

• 30% loss in optical stack in order to create uniform light.

• a 25% loss in pixel aperture (interconnect, transistors).

Additional limitations include light leakage through the LC cells, causing poor black levels, reduced contrast ratio, and a viewing-angle-dependent variation of display gamma.

The actual lights in the backlight – LEDs vs. CCFLs – also play a role in the efficiency of LCD panels. Conventionally, white LEDs were mainly used in mobile-display applications because CCFLs require high voltages and are comparatively fragile and bulky. White LEDs have now surpassed the classic CCFL in luminance efficiency for a given power input and are approaching the same cost-per-unit level. In the last couple of years, white LEDs have rapidly taken over market share from CCFLs in the notebook realm as well. The desktop-monitor market has also followed suit, and this year, LEDs began entering the LCD-TV market in full force, enabling 50-in. display modules of less than 10 mm in thickness.

The Green Screen

Depending on the application, about 20–50% of the overall energy of multimedia applications such as computing and TV is required by the display alone. This balance gets even worse for increasing screen sizes because the larger screens require the same luminance per square meter. For example, the display of a 21-in. monitor needs twice the energy of a 15-in. monitor, and the display of a 56-in. jumbo TV requires a factor of four more energy than a modest 28-in. TV.

Despite the energy cost of the larger panels,the market is trending toward bigger and bigger screens at the same time that government energy regulations and energy-label programs for TVs are coming increasingly into play. Successful display technologies for TVs must be able to display superior imagery while also using less energy. Due to advances in LED-backlighting technologies, LCD TV is well-suited to meeting those challenges. This article will discuss backlighting approaches with regard to CCFLs as well as LEDs where applicable, but the future of LCD-TVs appears to lie with LEDs.

Adaptive Dimming

The luminance for LCD TVs can now be controlled spatially as well as temporally, especially with the introduction of LEDs as a backlighting source. By tailoring the backlight to generate light only at the time and location where is it actually needed, image contrast can be improved, and at the same time less power is consumed. This technique is frequently referred to as "dynamic backlighting" or "adaptive dimming" and requires special driving electronics and algorithms to achieve an optimal system performance.

Adaptively dimming the backlight significantly improves the performance of an LCD module and enables better contrast and power efficiency. When the backlight in the darker parts of images is dimmed, the light leakage through the liquid crystal is reduced and the dynamic range is increased as well, thus improving the contrast of the panel. Also, the average power consumption is reduced because the LEDs are creating less light, they need less energy. Dimming also often improves picture quality for different viewing angles.

It is also possible to use the power saved by dimming in darker areas to locally boost the luminance of bright areas of images, thus achieving a more vivid picture. For this approach, LEDs can be conditionally boosted in luminance by being driven at a higher than nominal current for a short period of time. However, special care must be taken in the thermal design of the backlight and LED drivers to prevent overheating of the LEDs.

Global and Local Dimming

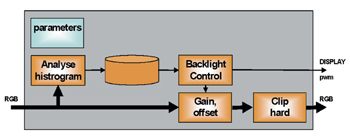

Two basic approaches toward dimming, which can be used with either CCFLs or LEDs, are global dimming, a methodology in which the entire backlight is dimmed by a single factor in each frame, and local dimming, in which regions within a frame can be dimmed separately. For global dimming, the luminance of a backlight is modulated with a dimming algorithm, relative to the video content (see Fig. 2). The dimming algorithm ensures that, while the backlight is dimmed, the video images are not reduced in perceivable luminance, so that picture quality is preserved. A complementary luminance modification of the image delivered to the LCD panel is required, which increases the video-processing requirements of the system.

A histogram is determined by analyzing the pixels of the image content in each region, which is used as input for the dimming algorithm. When a darker scene is detected, the backlight is dimmed in combination with a complementary change in the gain of the video content shown on the LCD. As light leakage is reduced, this also improves the saturation of the dark colors. For brighter scenes, the required higher luminance levels are driven and less video gain is required.

Fig. 2: A global-dimming algorithm is represented in a block diagram.

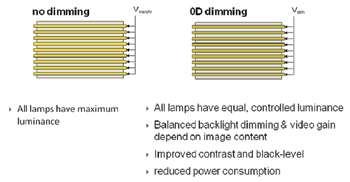

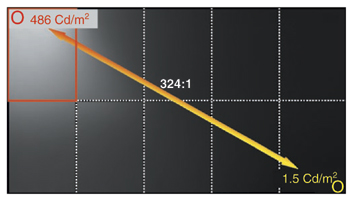

Because there is no control over the luminance in the spatial domain, the global dimming technology is sometimes called 0D dimming, as shown in Fig. 3.

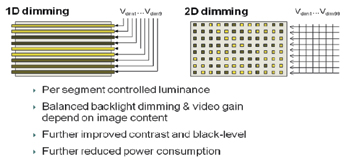

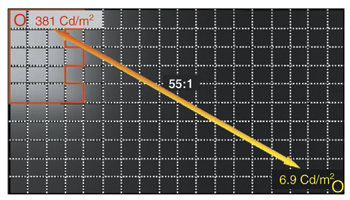

In local dimming, the backlight comprises a number of small 2-D segments, each having a luminance that can be modulated. A segment may comprise single or multiple light sources. For CCFLs, which are shaped like tubes, local dimming can only be applied in one dimension (1D dimming).1 2D dimming, which is possible with LEDs, allows greater control, as shown in Fig. 4. However, as 1D and 2D dimming require individual drivers per segment, the cost for implementation will be greater.

When no regions are dimming, the backlight produces its maximum luminance and should have a uniform light profile. When there are differences between the segments, these need to be averaged out by the optical system, so a smooth light profile per region with overlap to its neighbors is desired. However, this optical mixing is actually a type of crosstalk that reduces the effective spatial bandwidth of the dimming backlight. An advanced local-dimming algorithm can compensate for this effect and improve the performance.2,3

RGB LEDs and Local Color Dimming

It is possible to employ a backlight with a combination of red, green, and blue LEDs that is driven at a constant, white color. However, RGB LEDs are expensive, less power efficient, and much more complex to work with compared to white LEDs. There is currently only one reason for using colored LEDs – their wider color gamut. Local color dimming is an approach toward a more power-effective RGB-LED solution. This technology involves executing the local-dimming algorithm independently for the red, green, and blue primary colors because the light sources are red, green, and blue LEDs with their luminance controllable per color and per region. This enables a larger color gamut. Still, the LED cost and power efficacy make this option unattractive.

The light profiles for each color do not need to be identical, although all segments together need to be homogenous; the data of the segment profiles need to be stored per color. However, it is not necessary to put the R, G, and B triplet in a single package, which makes the thermal design easier because it leads to smaller temperature differences. Yet, this approach is expensive as well.

A big difference between local (white) dimming and local color dimming is that the latter offers more opportunity to compensate for color errors. But there is also more need to do so. Color dimming introduces larger temperature differences, which may cause drift in the color and brightness. There is a greater need to preserve the realistic colors, especially if RGB LEDs in a single package are used. If, e.g., the blue and green LEDs are dimmed, the temperature of the red LED will drop as well because they share the same heat sink in the package. Hence, the red LED will become more efficient and, as a consequence, the color of the triplet may shift more towards red than desired.

Local Dimming and Edge Lighting

Thus far, this article has discussed backlighting for direct-backlighting applications. However, edge-lit backlights, in which all the light sources are placed at one or more edges of the display, are commonly used for notebook computers. A special light guide is required to distribute the light from the edges over the panel area for a homogeneous backlight. The main advantage of edge-lighting is the very thin form factor.

Fig. 3: The CCFL backlight example shows the advantages of 0D dimming or global dimming at right.

Fig. 4: Shown on the left is 1D dimming with CCFLs and on the right, 2D dimming with LEDs.

For TV panels, slimness is quite desirable, but until recently it was not possible for larger LCD screen sizes to also be very thin. This is due to the fact that the required amount of light (flux) is proportional to the screen area while the length of the edges is proportional to the square root of this area. Hence, the larger the panel, the higher the required light density at the edges.

With the development of more effective LEDs and improved optical design, it is now possible to produce very slim LCD panels with an edge-lit backlight, even for display sizes of 56 in. and larger. LEDs can generate the required light densities so efficiently that their temperature is still acceptable. The backlights are less complex and less expensive than a comparable direct-backlighting system; however, the power consumption of these solutions is about 130% of a comparable direct-lit backlight due to optical losses caused by the light guide.

Here, local dimming can provide a solution. While many believe that edge-lit backlighting technology cannot be combined with local dimming, it actually can. Obviously, edge-lit backlights with LEDs as the light source cannot be segmented in a narrow 2D grid as is the case with direct-lit LED backlights. But still, we can distinguish the top from the bottom of the screen. And in the horizontal direction the segmentation can be as narrow as the number of LED strings used in the design. In fact, as shown in Fig. 5, an LCD TV with a 2D edge-lit backlight can have a higher spatial contrast (with high-dynamic-range improvement) than a direct-lit backlight LCD-TV.

Because the optical segments of the local-dimming edge-lit backlight have an irregular shape, a special version of the 2D dimming algorithm is required.

NXP showed a prototype of an LCD TV with an edge-lit backlight with 10 segments at the CES 2009 and IFA 2009 shows and presented a paper on the topic at Display Week 2009.4 In this example, the top and bottom of the backlight use five strings consisting of 16 LEDs to illuminate the panel, enabling a two-dimensional dimming-backlight algorithm. The average power savings through this architecture is twice the savings of a global-dimming algorithm. This means that a very slim LCD TV using this technology will on average consume less energy than a comparably sized CCFL unit.

(a)

(a)  (b)

(b)

Fig. 5: The edge-lit example (a) at left shows relative spatial contrast (high dynamic range) improvements over the direct-lit example (b) right.

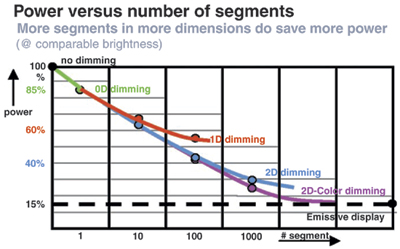

Fig. 6: In general, the more segmented the dimming technology, the more power is saved.

Conclusions

Figure 6 shows the impact of the different backlighting technologies on the performance of an LCD system.

To summarize, dimming-backlight technology saves system power and improves the picture quality of LCD applications such as TVs. White LEDs are the best light sources to be used with dimming because they are small and have become power efficient and competitive in system cost. Both direct-lit as well as edge-lit LCD panels using LEDs enable 2D dimming, which saves the most power.

For wide-gamut applications, RGB-color LEDs can be used in the backlight, enabling local color dimming and increasing the gamut even more. Yet, this technology is currently too expensive for practical use. Lastly, local dimming introduces temperature gradients in the backlight, which change the efficacy of the LEDs. This has an impact on the optical uniformity as it introduces flux variations with respect to the measured backlight profile. The error is proportional to the optical crosstalk; hence, more power savings can be achieved when temperature feedback is included in the algorithm. The video processing required for local dimming requires significant processing power, yet this can be embedded in existing programmable video processors.

References

1P. M. de Greef, H. W. Groot Hulze, J. Stessen, H. van Maurik, and S. Sluyterman, "Adaptive 1D Scanning, Dimming, and Boosting Backlight for LCD-TV Systems," J. Soc. Info. Display 14/12, 1103-1110 (2006).

2H. W. Groot Hulze and P. M. de Greef, "Driving an Adaptive Local Dimming Backlight for LCD-TV Systems," SID Symposium Digest39, 772-775 (2008).

3P. M. de Greef and H. W. Groot Hulze, "Adaptive Dimming and Boosting Backlight for LCD-TV systems," 38, 1332-1335 (2007).

4H. W. Groot Hulze and P. M. de Greef, "Power Savings by Local Dimming on a LCD Panel with Side-Lit Backlight," SID Symposium Digest 40, 749-752 (2009). •

Pierre de Greef is a system architect with NXP Semiconductors/Display Solutions, Eindhoven, The Netherlands. He has more than 25 years of experience and is working with his team on silicon and software solutions to improve the performance of display systems. He can be reached at pierre.de.greef@nxp.com.